BHP

Laura Bishop

5.00 AM

My alarm goes and I hit snooze a few times before finally summoning enough energy to roll out of bed. I get ready for the day ahead, changing into my high-vis uniform and packing everything I’ll need for the day into my backpack.

5.30 AM

Once I’m all ready and packed up I head down from my donga towards the ‘Dry Mess’. It’s a large cafeteria on site that has a big range of breakfast foods to choose from each morning. As tempting as it is to go for a full fry-up with bacon, eggs and waffles, today I opt for some muesli from the cereal bar and sit down to watch the morning news which is being broadcast on one of the TV screens in the seating area. Once I’ve eaten my breakfast, I head over to the lunch packing area, where I collect my ‘crib’ aka my lunch and snacks for the day. I usually grab one or two things from the pre-made food fridges - these usually stock a range of sandwiches as well as several different ‘hot’ meals which can be heated up in a microwave later. I also make a customised salad, picking and choosing various options from across several bain-maries’ worth of ingredients, before grabbing a few pieces of fruit and heading off to the office.

Unlike many people who stay at Mulla Mulla Village, I’m very lucky because the office I work in – the South Flank Exploration Office – is based right on site, only a couple of minutes' walk from both my donga and also all the other main facilities on site, including the gym, Dry Mess, Wet Mess and The Last Flank shop. On my short walk to the office, I pass by a number of night shift workers who’ve just arrived off the bus from Mining Area C and are now headed to grab themselves some food or drinks before heading to bed for the day.

6.00 AM

I swipe my BHP card on the card reader to clock in for the day and then head to the back of the office where all the Geoscience teams sit. After logging into my computer and checking a few emails, I make a start on helping to fill out the Mine Geology Team’s morning meeting spreadsheet. Every day during our 6.30 am morning meetings we go through and discuss everything included in this spreadsheet, as the information that’s in there helps to summarise everything that happened yesterday, as well as allowing us to plan what work needs to be done today and where. The Central Mine Geology Team covers both the Mining Area C (MAC) and South Flank sites, so we often have team members working out of both offices, but it also depends on where the majority of the fieldwork that needs to be done that day is, or if we need to attend any particular stakeholder meetings.

The Mine Geologist team members who have been put in charge of ‘grade control’ spend this morning preparation time tracking the movements of the excavator and dump trucks over the past 24 hours, so that they can make sure that all the material that was dug up during this period has ended up in the correct stockpiles and/or waste dumps. They will then further investigate any anomalies or unexpected material movements that might have occurred. For example, if designated ‘waste’ material was accidentally taken to a high-quality iron ore stockpile or fed through a crusher, the grade control Mine Geologist might need to talk to the Daily Schedulers and figure out why and how this happened, as well as how to stop it happening again. The grade control Mine Geologists will also look at what, if any, fieldwork needs to be done throughout the day so that they can head out at the right time, usually to beat the midday heat or avoid getting caught in a passing storm.

This swing, however, my role is that of the ‘sample lead’, and as part of this role, I spend this morning preparation time checking to see which drill patterns have finished being drilled within the past day, as well as if there are any drill patterns for which the sample data has been analysed and returned such that we can start planning how to most effectively mine this pattern through creating a ‘blockout’ map. I notice during my checks that there is a drill pattern that the Production Schedulers want to be mined in the next few days, so I send a request to the sample analysis laboratory in Newman to ask if the samples from this particular pattern can be prioritised so that we can start creating a blockout map as soon as possible based on this data.

6.30 AM

Once we’ve all filled in all the necessary information into our team spreadsheet, the team heads over to the meeting room for our daily morning meeting. We start each meeting with at least one or two safety shares from the day before, as well as taking the time to check in with each team member about how they are feeling, physically and mentally, so that we can plan the day as to be as safe as possible for everyone and delegate any work if needed. We then go through the plans for the coming day in the meeting, including any upcoming meetings, tasks that need doing and/or prioritising, and any ideas or general business announcements that team members want to share. During this morning’s meeting, one of the team members highlights that there’s some field work that needs to be done in a few of the MAC pits this morning and asks for any volunteers to help them with that work. As I don’t currently have any urgent desktop work that needs to be done, I volunteer to come along. My favourite part of this daily meeting, though, is at the very end when we take the time to shout out and celebrate any particularly good work done by one or more of our team members the previous day!

7.00 AM

Today’s weather forecast predicts a midday temperature of over 40 degrees, so my colleague and I waste no time getting ready to head out into the field to get our fieldwork done. We grab our lunches from the fridge, make sure we have all the PPE we will need and head out to one of the Mining Geology cars parked outside. The drive to MAC office only takes us about 20 minutes, and we quickly drop our belongings at the designated MAC Mine Geology desks before heading out to the pits.

7.30 AM

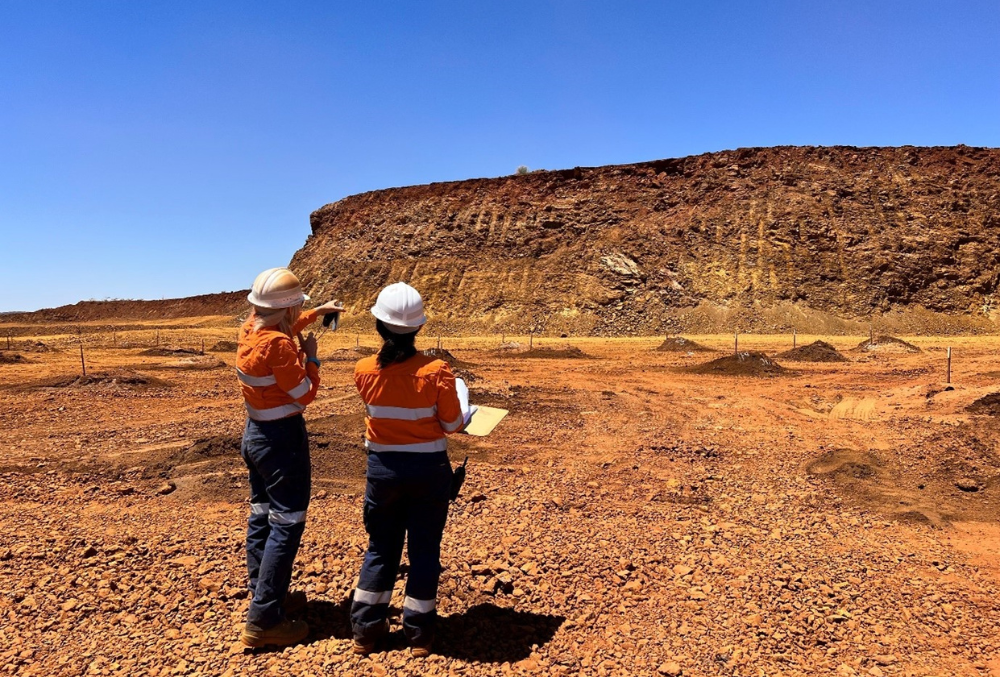

We head to one of the drill patterns that are about to be mined in a few days and where some ‘face mapping’ is required. What this entails is going to any of the designated pit walls around the edges of the drill pattern and making notes about the stratigraphy, as well as any structural elements we see, such as folds, faults, jointing, etc. This information is then digitised and released in a face mapping report, which is used by various stakeholders, such as modellers and geotechnical engineers, for a range of purposes, namely, to better constrain and understand the geology as well as the structural integrity within this area of the pit.

My colleague and I do a quick walk around the wall to make some more general notes about the overall features and stratigraphy we see. We then go back to the start and my colleague walks right up to this first part of the wall and uses their compass to take a measurement of the bedding plane. I stand 10m away from the wall as a spotter – this is a safety precaution in case of unexpected rock falls - and I write down all the notes and measurements my colleague tells me into the app that we use for recording all our mapping data. My team member and I then swap roles, walking down the length of the wall and taking various measurements of the various geological features and structures that we see until we are satisfied that we have enough measurements to properly represent this section of the pit wall.

9.30 AM

We have a bit more fieldwork that needs doing in one of the other pits, but first we must head back to the MAC office for the daily morning MAC Production Meeting whereby the upcoming mining plans are discussed for the day. As Mine Geologists we don’t have to do much for this meeting, aside from answering any geology-related questions or follow-up any requests for further information and/or investigation into any potential issues or concerns raised by one of the other stakeholders at the meeting.

10.00 AM

Once the meeting is finished, we head back out this time to a pit that requires two different types of fieldwork - fibrous checking and floor mapping. We start first with fibrous checking. We must do this fieldwork in areas where previous exploration drilling campaigns have identified a potential risk of digging up asbestos-containing rocks within part of a drill pattern, so we have to go out to check that there isn’t any asbestos in this area before we can clear it as safe to mine. We grab protective masks and shovels from our car and walk to the potential fibrous risk areas highlighted on our maps. On this drill pattern, drill rigs have previously come in and drilled a number of holes, with the dirt that is pulled out during this drilling being stacked into piles or ‘cones’ next to the holes, which may later be shovelled into bags to be sampled. We then walk along to each of these holes and use our shovels to dig and sift through the dirt in each pile to check for any signs of asbestos material. Once we have made sure that none of the holes has intercepted any asbestos, we can let the other teams know that it is now safe to sample and mine this material.

It's getting quite hot by this point, so once we have made sure there is no asbestos risk, we can remove our masks and start the floor mapping. We take out a printed map that was created earlier based on the current geological model of that pit and walk around each of the blast hole cones to check if the predicted geology in the area is right, or if there are any differences in the stratigraphy and/or structures between the model and actual rocks that we see which need to be recorded. This allows us to improve our predictions of what is going to be good and bad ore when it comes to mining this area in a few days’ time.

After looking mostly at the colour and texture of the material in each of the blast hole cones, we decide to adjust some of the stratigraphic boundaries on the map so that it better reflects what we have observed about the geology of this pattern in the field. Then, once we are satisfied, we jump back in the car and drive back to the office.

12.00 PM

We’re feeling pretty hot and tired when we finally arrive back at the MAC office, so we decide it’s time to grab some lunch. I make myself a coffee and toast the sandwich I grabbed earlier this morning, and then we sit down at one of the tables in the cool air-conditioned crib room to eat and chat. It’s certainly very refreshing to have a nice sit down after walking around all morning!

12.30 PM

Once we’ve finished up with work, we set up for the afternoon to do some desktop work tasks, which is the majority of the work the Mine Geologists will do on a day-to-day basis in the team. There’s a large range of tasks we can do, depending on when and which patterns are set to be drilled or mined in the near future, and what our various stakeholders need. This includes various investigatory and analytical work such as finding more cost-efficient ways of mining a certain area or understanding why there might have been a large difference between the volume and/or quality of iron ore that was mined versus what was predicted in the model.

One of the main tasks we do is using the model and various data to understand the potential fibrous (asbestos) risk in areas set to be drilled or mined in the near future. Another major core routine is deciding the most efficient way of sampling a drill pattern to ensure we get as much data as possible whilst trying to reduce any unnecessary sampling i.e. in areas where we are already very confident about the geology, such that we can save costs and get the sampling results back as quickly as possible.

However, today I’ve decided to work on my blackout map. To create a blockout we take all the geochemical data that have within the drill pattern and use it to predict, to a relatively high degree of accuracy, the type and quality of ore that we would be expecting to be digging up in each area of the pattern. We break the pattern up into ‘blocks’ on about a 10m scale and try to decide the most efficient way of grouping each of these blocks to maximise the amount of good quality ore we can extract from a certain area, whilst also trying to minimise including as much waste material as possible. I find this work quite interesting to do because it requires a bit of creativity, problem-solving and often input from the other team members in order to find the best possible solution, especially in areas where mineralisation is very patchy or there are complex geological structures.

Once I’ve finished creating my blockout map, I will need to upload it for the diggers and haul trucks to use whilst they’re in the pit so that at any point they know what kind of material they should be digging up and where that material then needs to be stockpiled or dumped. I will also need to write up a short report explaining the decisions behind the blackout map I made, as well as some hypotheses for why this map may have produced a different quantity and quality of ore than predicted by the original geological model of the area. The most important part of this report is highlighting any potential risks for future mining in that area, such as if it was originally predicted for there to be lots of high-quality ore below the current bench, but then the recent sample data suggests it will mostly be waste material.

3.30 PM

Time for a quick tea break and a chat with some of the engineers that work on the desks near to mine, and then I head back to my desk to continue working on my block out.

5.00 PM

I realise it’s already gotten quite late in the afternoon, so my colleague and I decide to pack up our belongings and drive back to the South Flank office to rejoin the rest of our team members.

5.30 PM

After arriving back at the South Flank office, I set up my laptop to do a few last-minute bits and pieces of work that will help set me up for success during tomorrow morning’s meeting – I’ll be chairing this one, so I want to make sure I’ve got all the information I’ll need ready to go!

6.00 PM

At 6.00 pm I save all my work, close down my laptop and pack up my belongings into my bag. I walk with a few of my team members to the card scanner to tag out and we chat about meeting up for dinner later. I then wave them goodbye as I walk back up the path to my donga, which is located a few blocks away from each of their dongas. Once I get there, I have a quick shower to wash the thick coating of red dirt off my hands, legs and face and then change into my gym clothes.

6.30 PM

After checking through my phone for a while, I realised tonight is laundry night. I bundle up my worn clothes and uniform and walk to the laundry room located a few dongas away from mine. I pop my washing on, drop my washing bag back in my room and then head down to the smaller of the two gyms we have on-site at Mulla Mulla Village.

6.45 PM

My friend and I meet outside the gym as we signed up for the daily gym class. Today’s class is a spin class, although each day they usually alternate between either HIIT, barbells, core conditioning, stretch and flex classes or spin classes – sometimes a combination of these. My friend and I each hop on a bike and prepare to sweat!

7.15 PM

The class finishes and I head back up to the laundry to move my stuff over into the dryer machines, then pop back into my donga for another quick shower.

7.30 PM

I head down to the Dry Mess to grab some dinner and meet up with a couple of friends who are waiting by the entrance. There are usually a few different meat and vegetarian options in a buffet-style layout, so I load up my plate and head upstairs to the second story balcony. It’s usually the best place to eat dinner whilst watching the sunset or occasionally a lightning storm passing by in the distance. Once we’ve finished eating, my friends and I head back downstairs to grab an ice cream to go.

8.00 PM

We all walk back together chatting and eating our ice creams before we head our separate ways back to each of our dongas. I beeline to the laundry room to see if my laundry is dry yet – it’s not, so I decide to go for a brief walk around Mulla Mulla’s walking track whilst I wait for it to finish drying. There are a few others on the track tonight – some running, some on the phone, and some staring up at the bright stars overhead - it’s not a bad way to spend the next 20-30 minutes!

8.30 PM

After finishing one loop of the track, I return to the laundry and find my clothes have finally finished drying. I pop them all into my bag and return to my donga to hang them up in my wardrobe.

8.45 PM

It’s gotten a bit later than I would normally go to bed, so I quickly change into my pyjamas and jump into bed to read for a short while before I eventually fall asleep, ready to take on the various challenges tomorrow will surely bring my way!

Thinking of experiencing life as a BHP Graduate? Sign up to GradAustralia to receive job alerts for BHP